|

|

|

||||

|

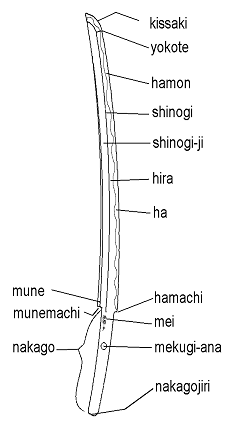

The parts and terminology in a Katana -

04-09-2007, 10:18 PM

Before I progress more into history or sword making I thought it would be informative to put up a diagram of a Katana with all its parts and their japanese names! So here goes...

I got this pic from Wikipedia!  Omae mo kanjite no ka... kaze no koe? |

|

||||

|

04-09-2007, 10:20 PM

this one's an older style, but it's a modern replica...i'll see if ican find a more traditional one

http://www.icefire-enterprises.com/Naginata.JPG tradtional naginata http://www.ginklai.net/images/galeri..._naginata1.jpg i couldn't find the modern variant i wanted, called a Dragon Naginata... also, sorry about not actually posting the pics...didn't feel like converting bitmaps again x.x |

|

||||

|

04-09-2007, 10:21 PM

Quote:

*Big hugs to OL and Carry*  Omae mo kanjite no ka... kaze no koe? |

|

||||

|

04-09-2007, 10:21 PM

"]*Claps* Great thread Ryuk!

And you dedicated some of it to me!!! HOW SWEET!!! And you dedicated some of it to me!!! HOW SWEET!!!  Ok, since I am such a history/myth/weaponmaking/nitty gritty detail fan, I wanted to post some of that type of stuff...  I know it;s a lot to read, and the orange does not help...good old Wiki...lol I know it;s a lot to read, and the orange does not help...good old Wiki...lolThe forging of a Japanese blade typically took hours or days, and was considered a sacred art. As with many complex endeavors, rather than a single craftsman, several artists were involved. There was a smith to forge the rough shape, often a second smith (apprentice) to fold the metal, a specialist polisher (called a togi) as well as the various artisians that made the koshirae (the various fittings used to decorate the finished blade and saya (sheath) including the tsuka (hilt), fuchi (collar), kashira (pommel), and tsuba (hand guard). The forging of a Japanese blade typically took hours or days, and was considered a sacred art. As with many complex endeavors, rather than a single craftsman, several artists were involved. There was a smith to forge the rough shape, often a second smith (apprentice) to fold the metal, a specialist polisher (called a togi) as well as the various artisians that made the koshirae (the various fittings used to decorate the finished blade and saya (sheath) including the tsuka (hilt), fuchi (collar), kashira (pommel), and tsuba (hand guard). The Japanese sword blade is formed from a combination of two different steels, a harder outer jacket steel wrapped around a relatively softer, inner core of steel. This creates a blade which has a hard, sharp cutting edge with an inner core which is resilient and able to absorb shocks in a way which reduces the possibility of the blade breaking or bending when used in combat. The hadagane, for the outer skin of the blade is produced by heating a block of high quality raw steel, which is then hammered out into a bar. This is then cooled and broken up into smaller blocks which are checked for further impurities and then reassembled and reforged. During this process the billet of steel is heated and hammered, split and folded back upon itself many times and re-welded to create a complex structure of many thousands of layers. The precise way in which the steel is folded, hammered and re-welded determines the distinctive grain pattern of the blade, the jihada, (also called jigane when referring to the actual surface of the steel blade) a feature which is indicative of the period, place of manufacture and actual maker of the blade. The shingane (for the inner core of the blade) is of a relatively softer steel with a lower carbon content than the hadagane. For this, the block is again hammered, folded and welded in a similar fashion to the hadagane, but with fewer number of folds. At this point, the hadagane block is once again heated, hammered out and folded into a ‘U’ shape, into which the shingane is inserted to a point just short of the tip. The new composite steel billet is then heated and hammered out ensuring that no air or dirt is trapped between the two layers of steel. The bar increases in length during this process until it approximates the final size and shape of the finished sword blade. A triangular section is cut off from the tip of the bar and shaped to create what will be the kissaki. At this point in the process, the blank for the blade is of rectangular section. This rough shape is referred to as a sunobe. The sunobe is again heated, section by section and hammered to create a shape which has many of the recognisable characteristics of the finished blade. These are a thick back (mune), a thinner edge (ha), a curved tip (kissaki), notches on the edge (hamachi) and back (munemachi) which separate the blade from the tang (nakago). Details such as the ridge line (shinogi) another distinctive characteristic of the Japanese sword, are added at this stage of the process. The smith’s skill at this point comes in to play as the hammering process causes the blade to naturally curve in an erratic way, the thicker back tending to curve towards the thinner edge, and he must skilfully control the shape to give it the required upward curvature. The sunobe is finished by a process of filing and scraping which leaves all the physical characteristics and shapes of the blade recognisable. The surface of the blade is left in a relatively rough state, ready for the hardening processes. The sunobe is then covered all over with a clay mixture which is applied more thickly along the back and sides of the blade than along the edge. The blade is left to dry while the smith prepares the forge for the final heat treatment of the blade, the yaki-ire, the hardening of the cutting edge. This process takes place in a darkened smithy, traditionally at night, in order that the smith can judge by eye the colour and therefore the temperature of the sword as it is repeatedly passed through the glowing charcoal. When the time is deemed right (traditionally the blade should be the colour of the moon in February and August which are the two months that appear most commonly on dated inscriptions on the nakago of the Japanese sword), the blade is plunged edge down and point forward into a tank of water. The precise time taken to heat the sword, the temperature of the blade and of the water into which it is plunged are all individual to each smith and they have generally been closely guarded secrets. Legend tells of a particular smith who cut off his apprentice’s hand for testing the temperature of the water he used for the hardening process. In the different schools of swordmakers there are many subtle variations in the materials used in the various processes and techniques outlined above, specifically in the form of clay applied to the blade prior to the yaki-ire, but all follow the same general procedures. The application of the clay in different thicknesses to the blade allows the steel to cool more quickly along the thinner coated edge when plunged into the tank of water and thereby develop into the harder form of steel called martensite, which can be ground to razor-like sharpness. The thickly coated back cools more slowly retaining the pearlite steel characteristics of relative softness and flexibility. The precise way in which the clay is applied, and partially scraped off at the edge, is a determining factor in the formation of the shape and features of the crystalline structure known as the hamon. This distinctive tempering line found near the edge of the Japanese blade is one of the main characteristics to be assessed when examining a blade. The martensitic steel which forms from the edge of the blade to the hamon is in effect the transition line between these two different forms of steel, and is where most of the shapes, colours and beauty in the steel of the Japanese sword are to be found. The variations in the form and structure of the hamon are all indicative of the period, smith, school or place of manufacture of the sword. As well as the aesthetic qualities of the hamon, there are, perhaps not unsurprisingly, real practical functions. The hardened edge is where most of any potential damage to the blade will occur in battle. This hardened edge is capable of being reground and sharpened many times, although the process will alter the shape of the blade. Altering the shape will allow more resistance when fighting in hand to hand combat Blacksmith Munechika (end of the 10th century), helped by a fox spirit, forging the blade ko-kitsune-maru ("Little fox"). The kami is represented by a woman surrounded by foxes. Engraving by Ogata Gekko (1859–1920), 1873. Attachment 1003 |

|

||||

|

04-09-2007, 10:23 PM

Quote:

I should mention here for the benefit of the rest that in the first link the actual length of the rod can be detached and only the hilt and sword used (when in close combat). If we notice carefully we'll see a small groove near the edge of the hilt close to the blade. That's the point where it can be detached...  Omae mo kanjite no ka... kaze no koe? |

|

||||

|

04-09-2007, 10:28 PM

OMG! You have got to be the kindest person on the planet! What a post! Wow!!! It would have taken me ages to write all that up, so thanx a bunch for helping out!  How could I not dedicate it to you. You're one of the 4 people who made me feel home at JF when I joined up  I'm going to post a sword making video or something! *Rushes to search for sword making video*  Omae mo kanjite no ka... kaze no koe? |

|

||||

|

04-09-2007, 10:30 PM

i was wondering about that

couldn't find a pic of the full Dragon Naginata, but here's the blade  |

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

|

|

Copyright 2003-2006 Virtual Japan.